Our Refinery Produces Mainly Crude Oil Related Products

Which are distributed to domestic markets and overseas export markets under the brand names of our Shareholders

ABOUT US

About US

Wellton Petroleum operates a refinery that is capable of processing 290,000 barrels of crude oil per day to produce fuel products and chemical feedstocks that are supplied to domestic markets and overseas export markets under the brand labels of its shareholders

Worldwide Petroleum

Exportation

HSEQ

We are committed to our goals of no accidents, no harm to people, no damage to the environment and total customer satisfaction. Our foremost priority is to secure the safety and health of employees, contractors and visitors. To this end, we strive to ensure the safety of our plants and assets as well as to minimise the impact our refinery operations has on the environment. Our efforts are also targeted at improving the quality of our products and services to meet our customers’ requirements. .

DRILLING

Based on what we have learned from the maturation phase, we assess the probability of finding oil and gas. Prospects that are considered the most geologically interesting are then explored through one or more wells. Before actually drilling the wells, we do not know which prospect will be successful. This emphasises the importance of having a broad portfolio with many options..

The P&W department is responsible for managing all procurement and contracts activities including warehouse operations to ensure the achievement of safety and quality specifications as well as the optimisation of costs in the supply of goods and services.

The refining process begins at the Crude Distillation Units (CDUs), of which there are three in our refinery. Crude enters the atmospheric distillation units and is distilled into different fractions, each with a specific boiling range. The fractions produced are further refined in various units to meet the specified product quality requirements. Most of the atmospheric residue is sent for vacuum distillation, separating vacuum gas oil and vacuum residue.

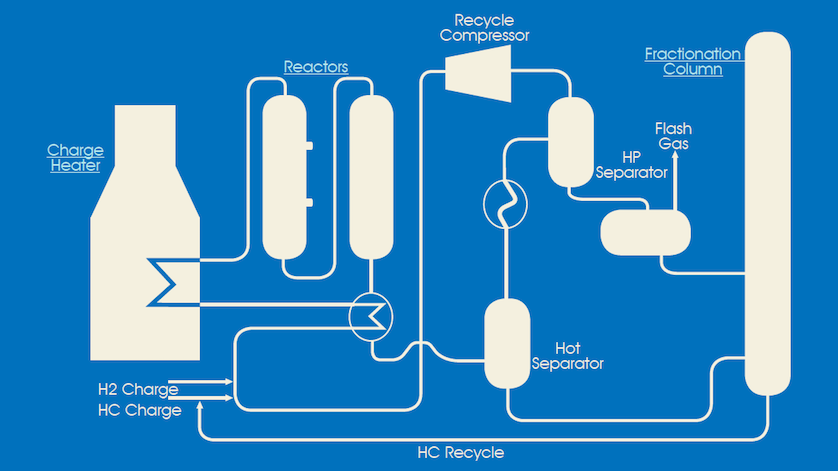

The Hydrocracker, employing the Unicracker Technology, enables the production of high quality and low sulphur middle distillate products, from heavy fuel oil components. Vacuum gas oil together with hydrogen are passed through the hydrotreating reactor to remove undesirable impurities, after which these are catalytically cracked through a process of high-temperature and pressure in the presence of catalysts and hydrogen. Products from the hydro cracking reactor are routed to distillation columns for product separation with some of the unconverted oil at the bottom of the fractionator recycled back to the hydro cracking reactor to increase the conversion. The presence of hydrogen in the hydro cracking process results in products with very low sulfur content and of superior quality that do not require further treatment. Lighter products such as naphtha, kerosene (jet fuel) and low sulphur automotive diesel form the main products.

SAFETY & LOSS PREVENTION

Integrated into every aspect of the refining operations, safety is fundamental and a work prerequisite for employees and contractors alike. The refinery firmly believes that incidents/injuries are preventable and recognises the importance of safety excellence to support continued business success.

RELATIONSHIPS

We are committed to creating mutual advantage in all our relationships so that others will always prefer to do business with Wellton Petroleum. Our approach is to maximize benefits not only for ourselves but also for all parties concerned with whom we have business dealings. We seek to foster understanding between ourselves and these parties as well as to build a sustainable relationship with them that is based on high performance standards, delivering on our promises, openness and flexibility, learning from others, mutual interdependence and sharing success. .